Brand Name: Tibright

Model Number: BAl

Place of Origin: Shandong, China (Mainland)

Material: Aluminum / Aluminum Alloy, Aluminium alloy, flux, binder

Diameter: can be customized

Melting Point: AlSi alloy:500℃-600℃ AlZn:400℃-500℃

Weight: other

Application: Radiator, refregerator, heat transfer, automobile, Aluminium alloy, stainless steel, titanium alloy

Flux Content: 0

Product Name: B2001 Aluminium Welding Brazing Alloy Filler Metal

Other Name: Aluminium Brazing Alloy Filler Metal

Standard: AWS A5.8, EN 1004, ISO 17672

Form: Wire, rod, strip, ring, powder, and paste

Working Temperature: AlSi alloy:500℃-600℃ AlZn:400℃-500℃

Industry: Radiator, refregerator, heat transfer, automobile

Feature: Good fluidity, high activity, high compatability

Expiration: 24 months

Aluminum brazing alloy is a very widely used brazing filler metal, especially in the industries of refrigerator, bike, car, etc. It is used to braze aluminum, aluminum alloys, and steel, copper alloys etc. It can be crafted to many forms, such as, rod, wire, ring, sheet, powder, paste, etc.

Aluminum silicon alloy brazing filler metal, especially AlSi12 (4047), is the first choice of aluminum brazing process due to its good melting behavior (eutectic alloy), low price, and high strength. Zinc-Aluminum alloy has low working temperature, it is suitable for brazing aluminum and copper alloys. It is widely used in radiator, compressor, and car pipe industry.

Zn-Al alloys has three main type Zn98Al, Zn95Al, Zn78Al, which are at melting temperature of 480 to 530C. The alloys should be used with low temperature aluminum flux.

Aluminum brazing alloys usually is used together with aluminum brazing flux.

Trade Mark |

Melting Temp |

Working Temp |

Tensile Strength(M.pa) |

Equal to |

Joint Gap |

Application |

|

As Usual |

AWS |

||||||

B-A188Si |

577-582 |

595-605 |

96 |

HL400 |

BA1Si-4/4047 |

0.1-0.25 |

High strength on joint gap, corrosion resistance. High temperature brazing, can be operate as hard torch brazing and furnace brazing. Use with aluminum brazing aluminum and aluminum alloy. |

B-A167CuSi |

525-535 |

550-590 |

98 |

HL401 |

0.1-0.25 |

Low temperature brazing, good fluidity. Good performance during brazing cycle. Easy to get compacted and high strength joint gap. Use with aluminum flux powder suitable for hard torch brazing aluminum and aluminum alloy. |

|

5356 |

880-909 |

940-960 |

5356 |

5356 |

0.05-0.13 |

High strength at joint gap, corrosion resistance. Use for aluminum and aluminum alloy with arc brazing. |

|

Trade Mark |

Components |

Melting Temperature |

Application |

|||||

Al |

Si |

Mg |

Zn |

Others |

Solidus |

Liquidus |

||

Zn98Al |

2 |

98 |

<1 |

430 |

440 |

High strength on joint gap, corrosion resistance. Use with low temperature brazing flux for brazing aluminum and aluminum alloys, aluminum-copper and aluminum-steel etc |

||

Zn95Al |

5 |

5 |

<1 |

380 |

390 |

Used with low temperature brazing flux for brazing aluminum and aluminum alloys, low temperature, good fluidity, good brazing technology. Easy to get compacted and high strength joint gap. |

||

Zn78Al |

22 |

78 |

<1 |

441 |

471 |

Good fluidity, used for brazing copper and aluminum, aluminum and aluminum alloys. especially suitable for the brazing and repair welding of air conditioning industry |

||

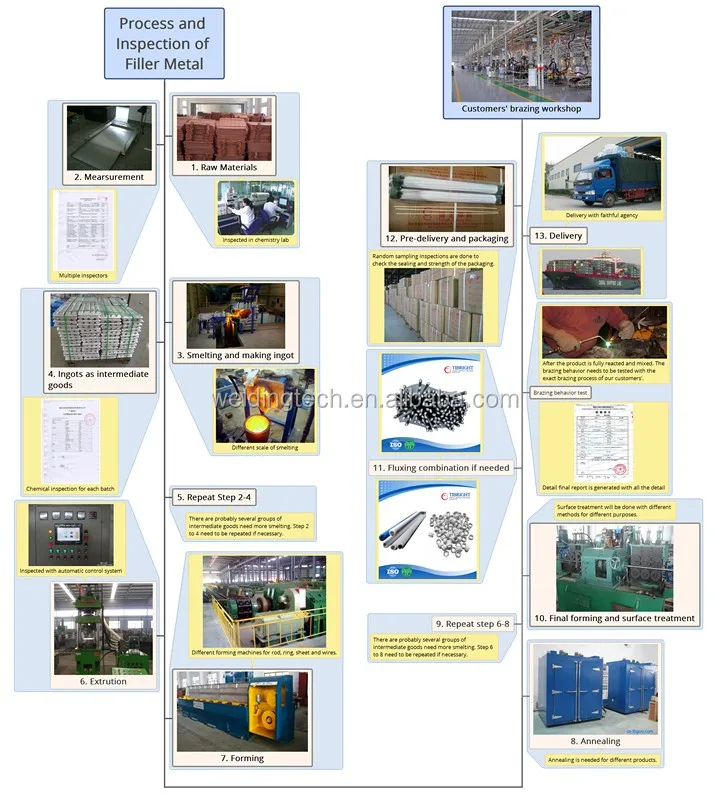

Yantai TiBright Welding Materials Co. Ltd., founded in 2000, is a professional developer and international supplier of inclusive brazing materials, equipment, and consultant. TiBright has hundreds of products for different applications. Customized products are also available for specific purposes.

When choose from our product library, please check out our recommended product list, If you have any questions, please let us know, We will try our best to satisfy your inquiry. Sometimes we need our customers to try different samples to make the perfect decision. Generally, we need to know the following information to choose a right product for you.

1. Materials of your parenting parts (to-be-brazed parts).

2. Heating methods. (eg. flame, induction, vacuum furnace etc. )

3. Atmosphere of application. (eg. room air, protective inert gas, reductive gas, vacuum, etc.)

4. Dimensions of your parts. Photos or graphs are preferred. (Different dimensions require different procedures.)

5. Current solution. (eg. brazing materials, equipment, procedures, etc.)

6. The reasons of searching new solution. (eg. price, strength, applicability, etc.)

7. Industry of your application. (Help us refer to similar examples.)

Normal package, other package can be customized according to customer's requirement.